We invite you to Saimdang Cosmetics Ochang Factory,

which has been further renewed with first-class technology and operating system.

Saimdang Cosmetics Ochang Factory, newly located in Ochang Science Complex and boasting a perfect operating system.

We work busily every day and night to make the best products in Korea based on the top-notch facilities and first-class technology in Korea.

Challenge toward the world through large-scale facility investment with domestic CGMP and overseas (international) GMP (ISO22716) certifications.

CGMP and GMPs that meet domestic and international cosmetic standards are prepared facilities to compete confidently in the global cosmetics market. They hold the new meaning of Saimdang Cosmetics for globalization completed with a first-class system

| Address | 143, Yangcheongsongdae-gil, Ochang-eup, Cheongwon-gu, Cheongju-si, Chungcheongbuk-do, Republic of Korea |

|---|---|

| Tel | 043-744-9292 |

| Plant Site Area | 16,497.10㎡ |

| Building floor area | 7,852.24㎡ |

| Building type | Factory, dormitory, restaurant, dangerous goods warehouse, warehouse, wastewater treatment plant, security building |

- Produces and ships 156 skin care and makeup items from 7 cosmetic brands on a total floor area of 2,500 pyeong, with the capacity to produce 1 million genuine skin care products per month.

- Produces SKIN CARE, HAIR CARE, BODY CARE, and quasi-drugs, and releases 10 functional foods.

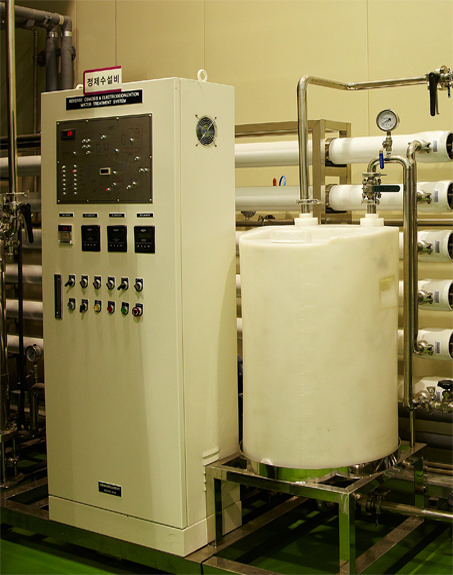

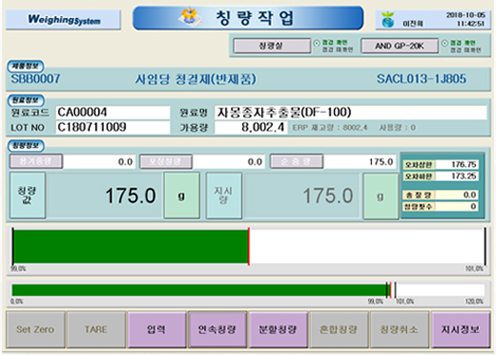

We have in place a lower-type manufacturing kiln that maximizes production efficiency and produces high-quality products, as well as the RO-EDI system, which boasts the highest water purity far more enhanced than before, and a raw material weighing system unified with a computer to ensure the product quality.

Mixer

2 units of 500L homo mixer,

2 units of 100L homo mixer,

1 unit of 1-2 ton open mixer each

Reverse osmosis-electrolyzer

We use active filtration facilities, micro filters, reverse osmosis (RO),

electrolysis ionizer (EDI),

and UV systems to produce purified water close to ultrapure water.

* What is Reverse Osmosis?

When an external pressure higher than the osmotic is applied to the high-concentration solution side, the solvent of high-concentration solution moves to the low-concentration solvent side, which is called reverse osmosis.

* EDI (ELECTRODE IONIZATION)

It is a device that produces high-purity water using an ion exchange membrane, ion exchange resin, and electricity.

When weighed according to research prescription, the raw materials are controlled and managed by the raw material weighing system. The accuracy of type and content is guaranteed by the computer program and stored in the data program.

We have a skin care product cell line and three 1-letter conveyor belt lines. Research Lab